Customers

Choice Fiberglass is a growing company that provides quality service to clients throughout the United States. Any industrial site that uses fiberglass fan blades can benefit from our services. We have had the privilege of working with a number of companies, including:

- Progress Energy (Duke Energy)

- CMS Energy

- Ecodyne

- Eagle Point Power Generation

- Entergy Union

DUKE ENERGY – ROXBORO, NC

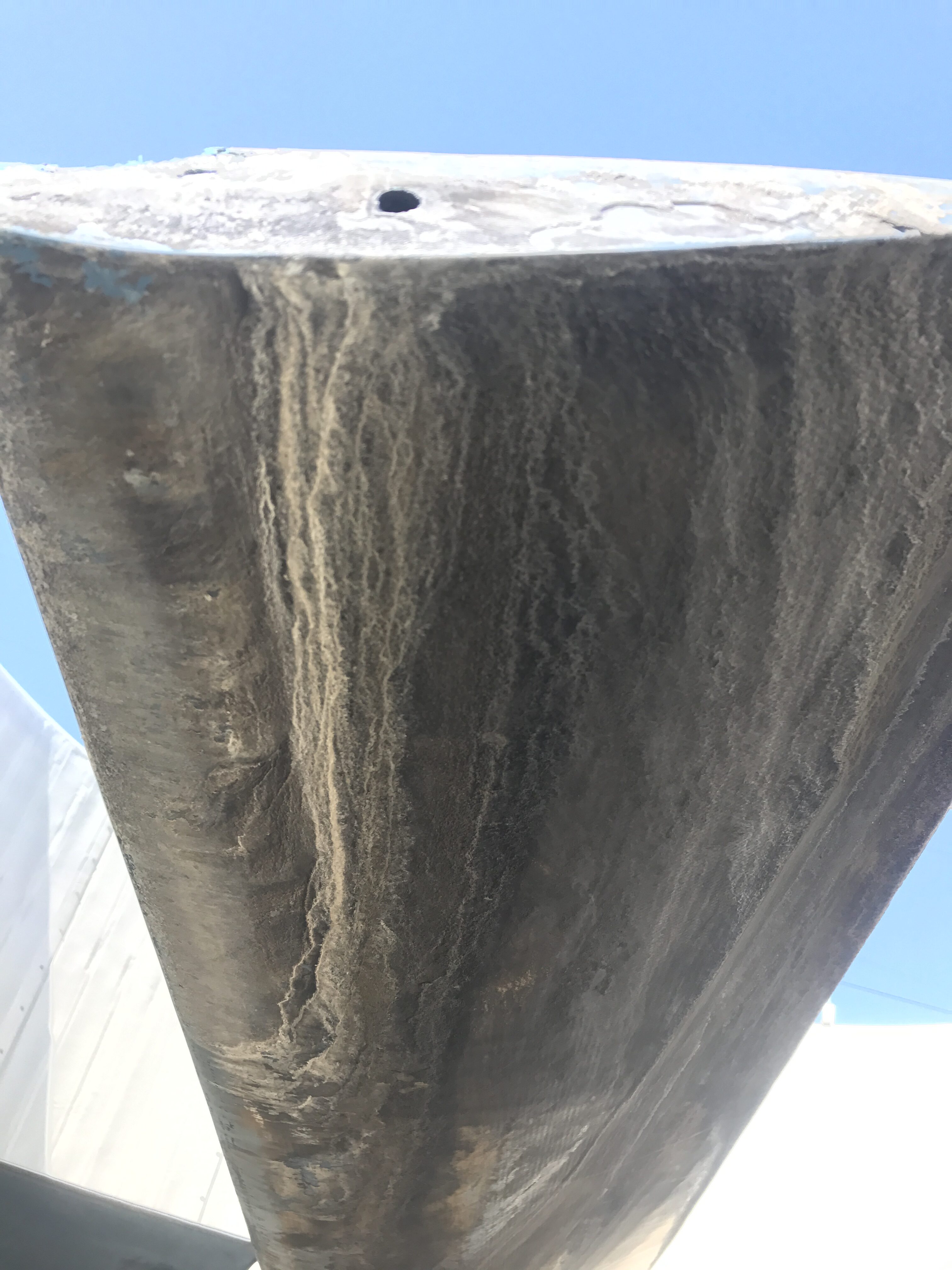

Problem: High-volume water and long service use caused erosion and extreme UV damage.

Solution: Stabilized all UV resin damage, rebuilt leading edges (including small perforations and erosion of trailing edges), and restored blades that would not have returned to service.

CENTRAL MICHIGAN UNIVERSITY – MOUNT PLEASANT, MI

Problem: Heavy UV damaged the composite resin and caused surface erosion.

Solution: Cleaned and stabilized loose surface material and protected the entire fan with an epoxy topcoat; repairs were completed with the fans in place (making only partial shutdown necessary), so the equipment was available for service soon after repairs were completed.

CMS GRAYLING GENERATING STATION – GRAYLING, MI

Problem: Harsh city treatment water caused edge erosion and heavy mineral buildup on the fans, along with limited functionality/lifespan.

Solution: Restored the cooling tower fan blades; these blades are used in an especially harsh environment due to weather and the fact that they are using available wastewater, but after six years (with two inspections per year), there has been zero charge.

Entergy Union – EL DORADO, AK

Problem: Impact damage while running. Damage to all blades in multiple locations.

Solution: Repairs completes using epoxy resins, fiberglass cloth and fillers. Blades returned to factory profile and completely recoated with epoxy coating and protected with a UV stable Polyurethane topcoat. Original balance retained, no adjustment needed.

Eagle Point – WESTVILLE, NJ

Problem: Heavy mineral buildup and contact with fan cowling.

Solution: Mineral buildup removed with abrasives and impact repairs completed using epoxy based repair materials. Blades were fully coated using submersible grade epoxy.

Arauco Wood Products – GRAYLING, MI

Problem: Protective coating failure caused by incomplete preparation and steel corrosion during transit from manufacturing to installation.

Solution: Steel cleaned and prepped for coating repairs using metal etching epoxy and top coated using factory matched enamel paint.